Development and Innovation

Quality

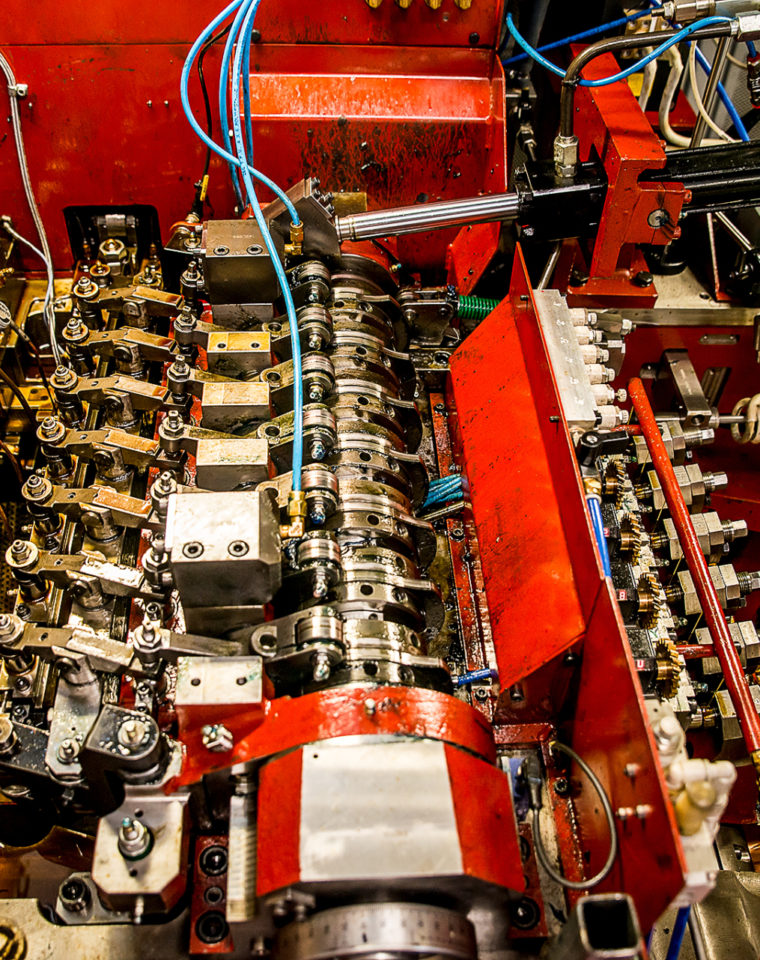

Pettarini has a strong inclination towards research and development, which has always enabled the Company to fine-tune innovative and highly competitive solutions. The Company's business is geared towards the creation of high quality products; it invests in constant technological improvement and in the careful selection of suppliers. Pettarini also bases its growth on the continuous and advanced training of its staff.

Research project

Pettarini is the beneficiary of the Operational Program for the use of the European Regional Development Fund for the period 2014-2020, which is the main instrument for regional development, for economic recovery and for employment support. In close collaboration with research institutes, a project has been started aimed at researching a new production methodology with cold molding techniques for the production of metal components for the automotive industry.

Pettarini leverages its many years of experience in the furniture sector and being aware of its skills explores other markets that are in search of new products and applications and can stimulate the operational readiness of the Company.

The challenge is therefore to create customised products, exploiting wire cold pressing technologies and guaranteeing the customer increased competitiveness and efficiency.

The challenge is therefore to create customised products, exploiting wire cold pressing technologies and guaranteeing the customer increased competitiveness and efficiency.

Benefits of cold pressing:

- Faster process

- Greater stability in the production process

- Greater accuracy on complex geometries

- Better surface finishing

- Savings in material

- Energy savings

The Company aspires to be constantly at the forefront and seeks technological excellence in strategic business areas. Over the years, Pettarini has collaborated with research centres and universities for the development of innovative ideas that can anticipate and meet the future needs of the market and the Company itself.

Along its research and improvement path, the attainment of the ISO 9001 and ISO TS 16949 certifications from the certification body TÜV-SÜD has been the natural evolution of a company that has always had as its main objective the continuous improvement of the production process at the service of the customer.

Along its research and improvement path, the attainment of the ISO 9001 and ISO TS 16949 certifications from the certification body TÜV-SÜD has been the natural evolution of a company that has always had as its main objective the continuous improvement of the production process at the service of the customer.

Key Benefits in the Production Process

With a precise analysis of customer needs and the design of innovative and customised solutions, Pettarini is able to satisfy all its diverse and demanding clientele.

With state-of-the-art production systems and the use of fast and accurate machines under electronic control, the Company can guarantee the quality of the entire production process.

Care of the environment

Pettarini aims to combine productivity and quality with respect for the environment. It undertakes to continuously review its environmental management policies to foresee the possibility of any improvements in order to comply with current regulations and to ensure continuous progress in terms of energy costs and environmental impact.

The Company supports initiatives to protect the places where we all live and is constantly committed to improving environmental quality both internally and externally.

It undertakes to promote and maintain the separation of waste collection, relying on specialised companies for the disposal of hazardous and non-hazardous waste, in compliance with current regulations.

Particular attention is paid when planning new activities, designing changes to existing work processes and investing in the purchase of new machinery, by carrying out a prior assessment of the environmental impact that those changes may involve.